Discovery Center at South Lake Union

Project Overview

This modular "pavilion in the park" was designed to be demountable and transportable for future disassembly and reassembly at multiple future locations. Its first use was for an exhibit telling the story of Seattle's South Lake Union neighborhood—its past, present, and future.

Design & Innovation

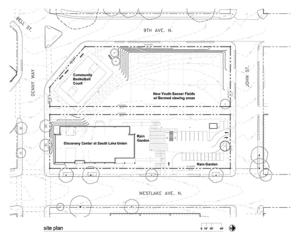

The project sits on the eastern edge of a full-block urban park that has been gifted to the city until the site is developed to its maximum zoning potential. As a temporary building, the structure sits lightly on the land, suspended above the gently sloping terrain atop short concrete piers. The building edges are cantilevered, allowing the grade and vegetation to run uninterrupted beneath.

Four-sided steel frame bents, bolted together, provide the structure for the building and span the interior gallery and exhibit space. The metal-clad building envelope components are designed as shop-fabricated, modular assemblies. The service functions of the pavilion are housed in a linear component that faces the park. Its softer wood materials and colors harmonize with the adjacent park and open space.

Presentation centers for residential developments such as this one typically have very short lifespans, since they disappear after construction is complete and the units sold. The modular nature of the project will allow it to serve for a much longer period of time. The building separates at three integrated joints to break into four separate modules capable of being transported along surface streets, where the building may resume functioning in its current capacity or be reprogrammed for an entirely new use.

Regional/Community Design

Although the entire site is privately owned, the siting and design of the structure, parking area, and open space took into consideration the use of the facility and grounds by the general public. The site is centrally located within an emerging neighborhood of residential communities, offices, and nearby private schools, and provides the only available green space suitable for field activities. Development of the site included grading work to level the field area for use as soccer fields for the Seattle Parks Department. Seattle Parks uses the field for organized public activities, including youth soccer and volleyball, and the nearby private schools use the field for recess. The southwest corner of the site also offers a full-size paved basketball court for public use.

The building is located at the intersection of two arterial streets and invites pedestrian interaction. In addition to hosting exhibit space showing the history of the neighborhood free of charge, the facility is available to residents of the community for private meetings and after-hours functions. The Discovery Center hosts summer block parties for the neighborhood and an outdoor film series during the summer months.

The site is easily accessible via public transit with two bus stops at the corner serving numerous routes. The South Lake Union streetcar also runs along the Westlake Avenue corridor with a stop adjacent to the Discovery Center. The Seattle Zoning Code required at least 28 off-street parking stalls; 22 are provided on-site, while the remaining six are located across the street. The off-street parking area also includes a reserved space for a car belonging to a car-sharing program.

Land Use & Site Ecology

The building sits lightly on the land, preserving the sloping terrain through the use of cantilevered steel frames set on short concrete piers.

A form of a green area ratio factor, pioneered in Berlin, Germany, has been adopted by the City of Seattle as part of its zoning code. The Seattle Green Factor program calculates a score (a “green factor”) for a site based on the area of lawn or grass pavers, number and maturity of trees and bushes, area of green roofs and walls, and other strategies. Buildings must achieve a green factor of 0.30 or greater. The Discovery Center served as a case study project for the program, and achieved a green factor of 0.51.

Bioclimatic Design

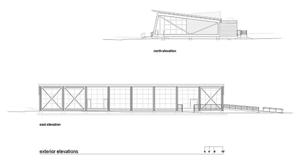

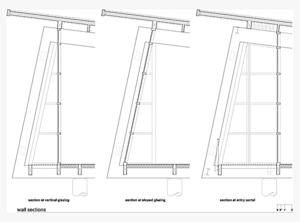

The project team conceived the building as an extruded linear form comprised of two spatially distinct sections. The main exhibit area required a flexible open space without structural walls or columns, and the service component for the building was to include back-of-house areas such as a kitchen, restrooms, electrical and mechanical rooms, and conference rooms. Extensive site analysis concluded the building should be sited near the corner of the active intersection of the two arterial streets, and parallel along the sidewalk of Westlake Avenue. A primary goal was to provide interaction between pedestrians passing by and the exhibits and activities inside and vice-versa. The east-facing facade along the sidewalk is opened up with expansive floor-to-ceiling glass, revealing the interior to Westlake Avenue and infusing it with abundant diffused natural daylight. The exposed wood roof structure of the main exhibit space slopes down toward the west, with one structural bay opening to a shed-roof dormer with a band of clerestory windows which frame a glimpse of the space needle from viewpoints inside. In contrast, the service bar of the building was conceived as a lower-height extrusion with fewer windows to control security and privacy for the back-of-house areas, but it also opens up with extensive operable windows and glass doors for natural daylighting and outdoor access at the conference rooms. The service bar exterior employs the transition from durable glass and steel surfaces at the exhibit exterior, to richly colored softer wood cladding facing the outdoor field and open space areas.

Light & Air

One of the goals for the Discovery Center was to create a “pavilion in the park” with an abundance of daylighting. East-facing, full-height glass fills the interior with comfortable ambient daylight throughout the day. The glass façade slopes inward as it reaches the highest point of the structure, while the exposed roof above slopes down toward the west, allowing daylight to reach deep into the space.

Overhead general lighting was reduced to a minimal array of surface-arm-mounted spot fixtures, strategically placed alongside the exposed roof purlins. These fixtures, typically screened by the purlins when viewed from the east side of the exhibit area, are mainly needed during evening hours. The presentation kiosks and informational displays throughout the space include dedicated low-voltage task lighting as required at each location.

Diffused natural light is provided in the restrooms with a band of translucent glazing. The conference rooms are provided with ample daylight, and operable windows provide natural ventilation at these rooms when desired.

Metrics

Water Cycle

The project utilizes a variety of techniques to manage stormwater runoff. Prior to construction of this facility, the site was a grass ball field with an existing stormwater detention tank. This tank was not large enough to handle added runoff from the building roof and paved areas, and a conventional design would suggest adding a new detention tank. The project team chose to use low-impact design strategies instead, slowing and filtering the stormwater on site so no new detention tanks were necessary.

Runoff from the roof is directed into a rain garden at the north end of the building, where deep biomitigative soils hold the water and allow it to evaporate. A rain garden along the edge of the asphalt parking lot serves the same function for runoff from the pavement and demonstrates the concept of "eco-street" frontage for urban areas. Much of the parking area uses a permeable paver system that allows rainwater to percolate into the ground. This approach decreased the peak runoff rate by an estimated 44% and the runoff volume by an estimated 37% for the design storm event, compared with a conventional building. The project team chose native and drought-tolerant plants to conserve water and provide wildlife habitat on site.

High-efficiency toilets and waterless urinals reduce the project's water use to just 45,000 gallons per year, a 15% reduction in internal water use, compared with a typical building of this type.

Energy Flows & Energy Future

Important considerations were given to the design of the mechanical and electrical systems to facilitate the demountable nature of the building. The electrical, lighting, and mechanical systems are each contained within the 40’ demountable modules for practical disassembly and reassembly. For instance, one smaller dedicated mechanical unit and associated supply and return ductwork is contained within each of the (4) modules to allow no ductwork to cross disconnect joints. In a similar fashion, all lighting and electrical conduit is contained within each module without crossing a disconnect joint. Below the floor structure, the main electrical conduit incorporates a disconnect junction box beneath each of the three separation joints, requiring only one electrical disconnect to occur between each module.

The building was designed to use no fossil fuels and instead uses air source heat pumps to heat and cool the building. The thermally-efficient building envelope, as well as the extensive use of daylighting and natural ventilation, allows this building to operate even in a blackout if required.

At the exterior site lighting, extremely efficient QL-variant electrodeless fluorescent lamps were used with a power consumption of only 85 watts, and a lamp-life of 100,000 hours. In lieu of overhead lighting at walks, low-voltage lighting mounted low, near walkway surfaces, is used to efficiently light areas such as pedestrian walkways and ramps.

Through careful design and installation techniques, the electrical and mechanical systems of the project will allow for a straightforward and simplified process of moving the building in the future phases of the building’s life.

Metrics

Materials & Construction

Several factors drove the selection of materials and design of assemblies, including durability, recycled content, and environmental responsibility. A primary goal was to design assemblies and select materials that would facilitate the required demountable aspect of the project.

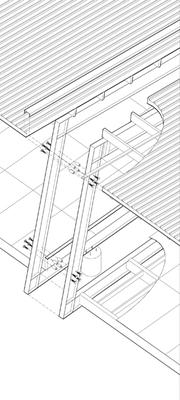

The steel frames were designed to incorporate shop-welded rigid corner connections with splice plates and exposed bolted connections at the vertical components of the bents. All of the frame components were painted off site, then transported to the site, hoisted into place, and spliced together quickly and efficiently.

The roof framing system was designed with glued-laminated beam purlins at 4-feet on center, spanning 20 feet from frame-to-frame, with oriented-strand-board sheathing spanning perpendicularly across the purlins without the need for any intermediate joist framing. Exposed laminated-strand-lumber blocking conceals the sheathing joints and provides the required edge for nailing. This approach allowed the roof system to be fabricated, sealed, and stained off site in 8-foot by 20-foot sections, which were then transported to the site and hoisted into place with a crane.

Environmentally responsible materials included 500 cubic yards of recycled concrete used as sub-base at the parking area; concrete containing flyash (50% at footings and piers and 30% at exposed slabs); composite decking planks with recycled content at exterior decking areas; paper-based countertops, partitions, and exhibit display casework; oriented-strand board and laminated-strand lumber; linoleum; and carpet with recycled content.

Long Life, Loose Fit

The primary program requirement of the project was to provide a flexible and adaptable interior exhibit space in a building that could be separated, moved, and reconnected.

The flexibility of the interior has allowed a significant portion of the exhibit space to be refitted since its initial construction to present a new series of residential communities coming on-line.

The contractor was involved during the design process to confirm the requirements for moving the building in the future. Module size constraints for street transport were identified, and joint connection designs were developed to ensure the future relocation would be successful.

The building employs three disconnect joints to break the structure into four modules, each 40 feet wide and 73 feet long. All interior and exterior finishes and assemblies have a built-in joint at this break point, covered by a removable plate, cap, or coping to suit each surface or location. This demountable aspect of the building is demonstrated to the public at the interior through the use of narrow aluminum closure plates on the floor and wall surfaces where they cross the disconnect joints. Barrier-free access to the main entrance and the catering kitchen is maintained by incorporating gangway ramps with integrated hinged joints, allowing the ramps to adapt to the topography of future building locations.

Collective Wisdom & Feedback Loops

From the project's inception, the project team included engaging and full participation by all parties, including the owner, the contractor team, and all design consultants. Early team meetings allowed for brainstorming of strategies and design options to enable the successful implementation of the environmental goals of the project.

As part of the jurisdictional process, public meetings were held to present the environmental goals of the project and receive public input. The aggressive environmental strategies were well received and welcomed in the previously hard-edged industrial environment of the South Lake Union area.

Since the building has opened, it has been a welcome addition to the neighborhood and has provided a dramatic backdrop to the demonstration of the environmental goals and strategies that can be adapted and integrated at other buildings and sites throughout Seattle and the Pacific Northwest.

Other Information

Although actual costs were not disclosed, the demountable nature of this building type provides for tremendous financial, building material, and embodied-energy savings.

Predesign

The project team engaged all parties early in the process to identify the primary environmental strategies and design options. The outcome of these sessions served as a basis for the design guidelines through the subsequent project phases.

Design

During the design phase, the project team held numerous public meetings to determine and address community concerns and goals, and to discuss how best to implement the environmental goals of the project.

Construction

The modular nature of the structure allowed for shop-fabrication prior to the start of site work. This not only provided a highly controlled environment for fabrication and finishing but also shortened the site construction phase as well as the overall construction schedule.

Post-Occupancy

After two and a half years of operation, staff and visitors alike continue to offer positive comments about the comfortable environment at the Discovery Center.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner/developer | Vulcan, Inc. | Seattle, WA | ||

| Contractor | Bill | DeJarlais | GLY Construction, Inc. | Bellevue, WA |

| Structural engineer | Jay | Taylor | Magnusson Klemencic Associates, Inc. | Seattle, WA |

| Civil engineer | Drew | Gagnes | Magnusson Klemencic Associates, Inc. | Seattle, WA |

| Landscape architect | Mark | Brumbaugh | Brumbaugh & Associates | Seattle, WA |

| Lighting designer | Candela | Seattle, WA | ||

| Electrical engineer | Jeff | Johansen | Cochran, Inc. | Seattle, WA |

| Mechanical and plumbing engineer | University Mechanical Contractors, Inc. | Mukilteo, WA |